Using a method of pasteurisation or sterilisation is necessary for almost all gourmet mushroom growing projects.

It’s often suggested that mushrooms have no trouble growing in nature without any human intervention. In nature countless spores of innumerable species of fungi are occupying every space, the vast majority of these spores will not produce mushrooms nor even germinate. The fortunate few that do are often condemned to produce small yields due to the enormous amount of competition & unfavourable conditions.

As a gourmet mushroom cultivator we challenge ourselves to produce the highest possible yields by maximising the biological efficiency of the fungi. This is achieved by reducing, or eliminating competing pathogens to ensure that the substrate and its nutrition are exclusively spent towards the production of the chosen fungi.

What Is Pasteurisation?

In terms of mushroom cultivation, pasteurisation refers to any method of processing a substrate that results in the reduction of competing pathogens. Pasteurisation will not completely eliminate all competing bacteria nor fungal spores.

These methods will allow for inoculation and subsequent colonisation without need for any special equipment.

Pasteurisation is ideal for beginners as it will often result in a lesser risk of contamination developing.

When To Pasteurise

Bulk substrates with little to no supplementation are suitable for preparation using methods of pasteurisation.

These substrates often include but are not limited to sugar cane mulch, straw, paper pellets and hardwood fuel pellets.

Substrates with small amounts of supplementation of up to 10 – 20% can also be processed with pasteurisation with varied results. Greater amounts of supplementation will often result in contamination developing and should be treated with sterilisation.

Cold Water Lime Pasteurisation

Cold water pasteurisation is a method commonly used for pasteurising large amounts of sugar cane mulch or straw without needing the addition of heat.

The substrate is submerged for over 16 hours in a bath of cold water and hydrated lime to reduce the number of competing pathogens.

Hot Water Pasteurisation

Hot water pasteurisation is considered by many to be a more effective method of pasteurisation than cold water methods.

Substrate should be fully submerged in water at a temperature above 80 degrees Celsius for 2 hours or more.

What Is Sterilisation?

Sterilisation refers to methods of substrate preparation which completely eliminate all organisms and spores.

This process will render the substrate prone to contamination and should be inoculated using aseptic technique for best results.

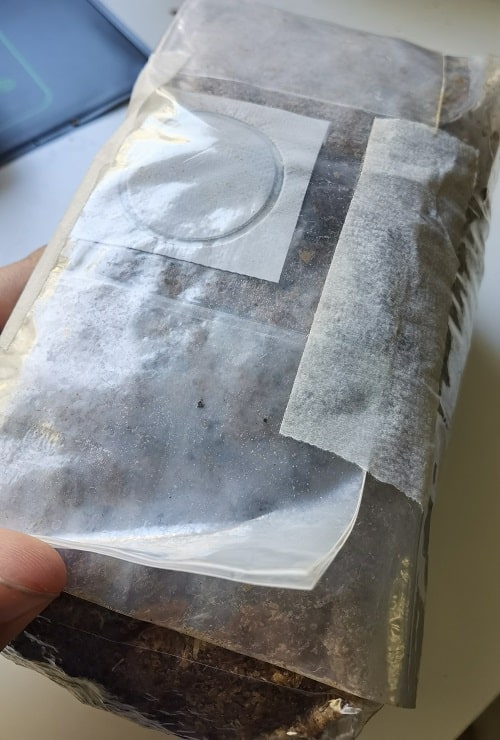

Special mushroom grow bags with a filter patch are used for sterilisation to allow for the exchange of fresh air without introducing pathogens while the mycelium is colonising.

When To Sterilise?

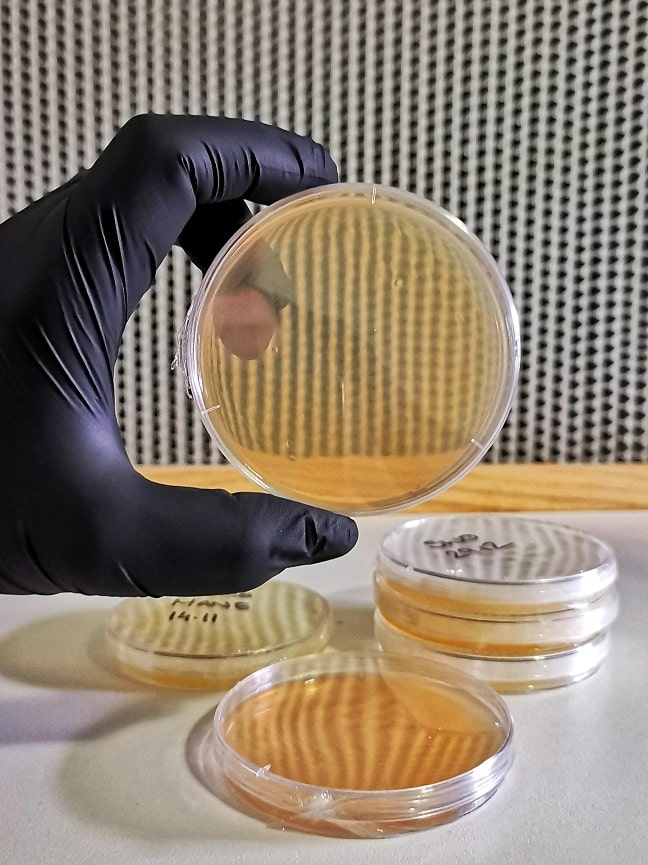

Sterilisation is used for the preparation of media like agar, liquid culture and grain spawn.

Media used in agar and liquid culture must be completely free from contamination in order to expand it exponentially to create clean and healthy master cultures or grain spawn for inoculating bulk substrates.

Any substrate with high amounts of supplementation must also be sterilised to ensure the healthy vigorous growth of mycelium.

Using An Instant Pot

An instapot or electric benchtop pressure cooker can be used for sterilising jars or even small bags of substrate.

The pressure in these units will usually only reach 6 – 8 PSI however processing times may be extended by 30 minutes if required to ensure full sterilisation.

How To Inoculate Sterile Media

Sterilised substrates are highly prone to contamination. For this reason they should be inoculated while following aseptic technique. Ideally this will involve the use of a laminar flow hood while undertaking inoculations to ensure that the sterilised media remains completely free from unwanted pathogens.

In the absence of a flow hood, inoculations may be undertaken in an enclosed space such as a bathroom however results will vary. An increased spawn ratio will encourage faster colonisation and lesser contamination.